Development of the Colburn Process

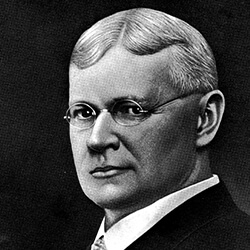

In the 19th century, flat glass was produced using a hand blown method, which had limitations in terms of productivity and quality. In 1905, Irving W. Colburn, a skilled machinist, began research and development of a continuous sheet draw process. In 1907, he built a small factory in Pennsylvania and as a result of his tireless efforts, produced a prototype machine. Unfortunately, the glass was not fit for sale.

Nevertheless, Colburn persisted and continued his experiments with the little capital he had left. In September 1909, he produced the world’s first sheet glass using his revolutionary new horizontal sheet draw process. However, with a string of mechanical problems and lack of capital, he was unable to continue further. In February 1912, he sold his Colburn process-related patents to Toledo Glass Company, an affiliate of the Owens Bottle Machine Company. Toledo invested additional capital and provided Colburn with a factory for his experiments. At long last, working together with Michael J. Owens, experiments proved successful, and in May 1916, the process was refined and Owens and Edward Drummond Libbey organized the Libbey Owens Sheet Glass Company. This company purchased all the patent rights for making sheet glass from Toledo Glass and built a modern factory in western Pennsylvania in 1917.

Importing the Colburn Process

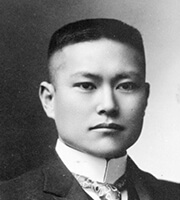

In 1885, Yosaburo Sugita was born in a wood and coal dealer family in Osaka. The Sugita family had close ties with the Sumitomo family, receiving deliveries of charcoal from Sumitomo’s Besshi mining plant. Sugita graduated from the University of Chicago in 1909 and afterwards, joined Shima Shoten (currently Shima Trading) in 1912. In 1914, Sugita visited the United States for negotiations to purchase glass bottle production equipment made by Owens. Sugita happened to tour the facilities of Toledo Glass Company and saw they were conducting experiments to commercialize the production of sheet glass using the Colburn process. Upon seeing this, Sugita became keenly interested in the sheet glass business.

After returning to Japan, Sugita quietly decided to change the Company’s manufacturing operations from glass bottles to sheet glass and in September 1917, went back to the United States and in New York, met with Yoshitaro Yamashita, manager of Sumitomo’s general headquarters. Sugita got Yamashita to support his desire to build sheet glass operations. Yamashita agreed with Sugita that pursuing the sheet glass business would be in the nation’s best interests. Sugita then negotiated with Edward Drummond Libbey (Libbey) to acquire patent rights.

However, negotiations were at a deadlock: While Sugita thought patent fees would be in the range of 2 million yen, Libbey did not want to hand over the rights at anything less than 4 million yen. After several negotiations, Sugita finally reached an agreement with Libbey and in December 1917, signed a patent right transfer agreement.

- *Key Points of the Contract

- Sugita would establish a new company for the manufacture and sale of flat glass.

- As patent fees, Libbey Owens would receive 20,000 shares of the new company (face value, 1 million yen, one-third of issued shares) and USD 100,000.

When Sugita signed the contract, Libbey had been producing glass products for only a few months, and Sugita was the only person in the world to have a license to this patent.

Establishment of America

Japan Sheet Glass Company

Establishment of America

Japan Sheet Glass Company

Upon his return, Sugita worked diligently to establish a new company. To reflect the participation of Libbey Owns, it was named America Japan Sheet Glass Company. The inaugural general meeting was held on June 25, 1928. However, there were many unexpected hurdles. The Libbey Owens certificate of investment required an original copy of the Colburn process patent, but due to an error, the patent right was cancelled in Japan. While another application was immediately submitted to restore the patent, it was not accepted and in October, the patent, albeit unexamined, was registered. Sugita went back to the United States, cancelled the original patent contract and signed a new contract. Upon his return, the inaugural general meeting was held on November 22 to establish America Japan Sheet Glass Company.

Installation of Colburn Process

machines and start of production

Installation of Colburn Process

machines and start of production

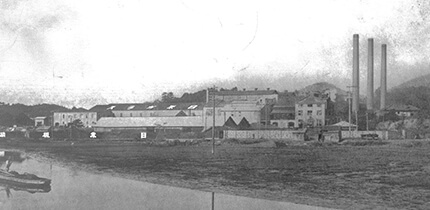

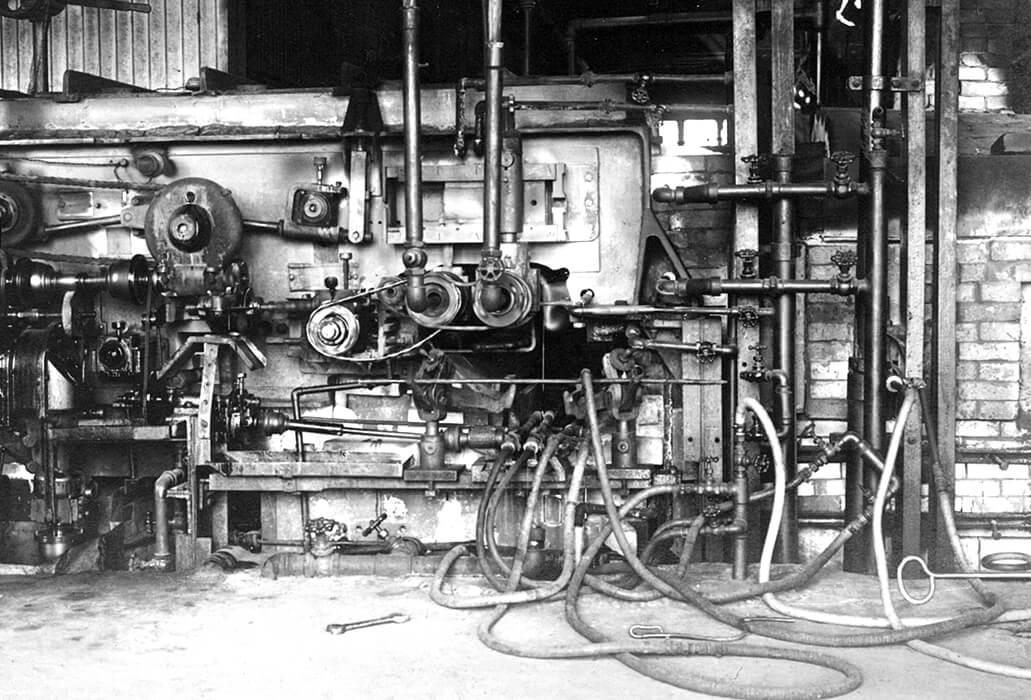

The new company decided to build a manufacturing plant in Futajima, Fukuoka Prefecture (now a part of the City of Kitakyushu) and construction of the Futajima Plant (to be renamed Wakamatsu Plant later) began in 1919. In December, Otto C. Miller and other engineers arrived from the U.S. to assist in the installation and operation of Colburn process machines.

At midnight on October 1, 1920, much-awaited glass draw process began.

Miller and other Libbey Ownes engineers were on hand when Colburn process machines were switched on, and by 1 AM, Japan’s first flat glass using the horizontal sheet process emerged onto the flattening table. At first, there were specks on the surface of the glass, but as the sun began to rise, they were able to produce 3 mm sheet glass, though not clear. By 8 AM, they were able to produce clear glass and the trial production was a success.